YARN - ANALOGUE HARDNESS DUROMETER

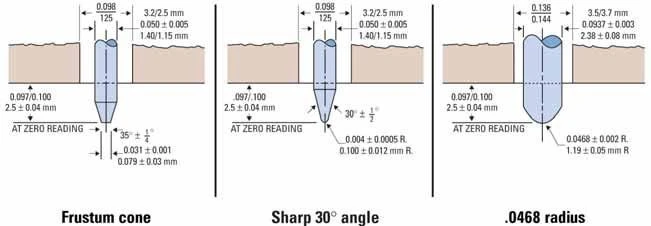

Indender Specification

Scale Selection Guide

The durometer selection guide will help you select the appropriate Shore hardness tester for your application. The combination of spring force and indenter geometry per ASTM D 2240-04 (as defined by ASTM DIN 53505, ISO 7619-1 and ASTM D 2240) determines the type of durometer required for a particular application. There is not one type of durometer that can cover the entire hardness spectrum. When selecting a durometer it is important to take the readings into consideration (readings below 10 or above 90 are not considered reliable). In such cases the next appropriate scale should be chosen.

| Scale of Durometer | Material to be used | Conforms to | Maximum Force | Indenter |

|---|---|---|---|---|

| A | Rubber : soft vulcanized (ie tire), natural nitrile. Elastomeric Materials (rubber & rubber like); GR-S,GR-1, neoprene, Thiokol, flexible polyacrylic ester. Other : wax, felt, leather, etc. (materials that normally yield under fingermail pressure such as the heel on you shoe). | ASTM D 2240 DIN 53505 |

821g | Frustum cone |

| B | Rubber: moderately hard (ie typewriter rollers, platens, etc.) | ASTM D 2240 DIN 53505 |

821 g | Sharp 30ºAngle |

| C | Rubber: medium hard Plastics : medium hard |

ASTM D 2240 DIN 53505 |

4533 g | Frustum Cone |

| D | Rubber, Hard Plastics: harder grades such as rigid thermoplastics, plexiglas, thermopolystyrene, vinyl, sheet, cellulode acetate, thermosetting laminates (ie formica) other : paper filled calendar rolls, calendar bowls, etc. (materials that would not normally indent under fingermail pressure, such as a pocket comb) | ASTM D 2240 DIN 53505 |

4533 g | Sharp 30ºAngle |

| DO | Textile Windings : very dense, slasher beams, etc. | ASTM D 2240 DIN 53505 |

4533 g | 0.0468 radius |

| E | Soft rubber, sponges and foams | ASTM D 2240 DIN 53505 |

821 g | 0.0980 radius |

| O | Rubber : soft (ie soft printer rolls, artgum) Textile Windings : medium density (ie rayon, orlon, nylon) |

ASTM D 2240 DIN 53505 |

821 g | 0.0468 radius |

| OO | Textile Windings : low density Other : sponge rubber and plastics (not for use on foamed latex) | ASTM D 2240 DIN 53505 |

113 g | 0.0468 radius |

| OOO | Plastic Foams : suit foams, open or closed cells | ASTM D 2240 DIN 53505 |

113 g | 0.25 radius |

| OOO - S | Plastic Foams : suit foams, open or closed cells | ASTM D 2240 DIN 53505 |

113 g | 0.25 radius |

| T | Textile Windings : medium density (on spools and bobbins with a maximum diameter of 101.6mm

94in)) Note : all XT’s have a concave bottom plate to facilitate centering or round specimens |

821 g | 3/32 in sphere | |

| M | Rubber : o rings and thin sheet min 1.25mm (0.05 in) thick. Complete with stand | ASTM D 2240 DIN 53505 |

78 g | Sharp 30ºAngle |