Shore D Hardness Tester | Hardness Checking Machine

shore d hardness tester, hardness checking machine

Welcome to Allonsy Ventures Private Limited, where we specialize in providing advanced Shore D hardness testers and hardness checking machines. As a leading provider of high-quality rubber testing equipment in India, we are committed to delivering exceptional products that meet the needs of various industries. Our cutting-edge solutions ensure accurate and reliable hardness measurements, enabling you to enhance the quality and performance of your rubber products.

Precise Hardness Measurements with Shore D Hardness Testers

When it comes to assessing the hardness of rubber materials, our Shore D hardness testers are your ultimate companion. These state-of-the-art instruments are designed to deliver precise measurements, allowing you to understand the hardness characteristics of your rubber products. By utilizing a specific indenter shape and applying a specific force, our Shore D hardness testers provide accurate readings that reflect the material's resistance to penetration. With the clear digital display and user-friendly interface, you can effortlessly obtain hardness measurements and make informed decisions about material selection and optimization.

Hardness Checking Machines: Unleashing Efficiency and Accuracy

In addition to our Shore D hardness testers, we offer advanced hardness checking machines that take hardness measurements to a whole new level. These machines employ cutting-edge technology to automate the testing process, increasing efficiency and accuracy. By eliminating human error and variability, our hardness checking machines ensure consistent and reliable results. With customizable testing parameters and user-friendly software, you have full control over the testing process, allowing you to streamline your quality control procedures and improve overall productivity.

Uncover the Power of Accurate Hardness Measurements

Accurate hardness measurements are essential for various industries, including automotive, construction, and manufacturing. The hardness of rubber materials directly impacts their performance, durability, and suitability for specific applications. By investing in our Shore D hardness testers and hardness checking machines, you unlock the power to precisely assess and control the hardness of your rubber products. This enables you to meet industry standards, ensure product reliability, and deliver superior quality to your customers.

Seamless Integration into Your Quality Assurance Process

At Allonsy Ventures Private Limited, we understand that efficiency and integration are vital for your quality assurance process. Our Shore D hardness testers and hardness checking machines are designed with your workflow in mind, allowing for seamless integration into your existing systems. The instruments can be easily calibrated and configured to meet your specific testing requirements. Whether you need to perform spot checks during production or conduct comprehensive hardness assessments in the laboratory, our equipment offers the versatility and flexibility to adapt to your needs.

Unparalleled Customer Support and Expertise

When you choose Allonsy Ventures Private Limited, you not only gain access to top-of-the-line rubber testing equipment but also benefit from our unparalleled customer support and expertise. Our team of knowledgeable professionals is dedicated to providing comprehensive assistance, from initial product selection to ongoing technical support. We offer training programs to ensure you make the most of our equipment, and our calibration services guarantee the accuracy and reliability of your hardness measurements.

Unlock Your Rubber Product's Potential with Accurate Hardness Measurements

Accurate hardness measurements are the key to unlocking your rubber product's true potential. By investing in our Shore D hardness testers and hardness checking machines, you can optimize the performance, durability, and reliability of your rubber products. Ensure compliance with industry standards, meet customer expectations, and gain a competitive edge in the market.

Contact Us Today for Exceptional Hardness Testing Solutions

Are you ready to take your hardness testing to the next level? Contact Allonsy Ventures Private Limited today to explore our range of Shore D hardness testers and hardness checking machines. Our team of experts is eager to assist you in selecting the perfect solution for your specific needs. Experience the power of accurate hardness measurements and elevate the quality and performance of your rubber products with our advanced rubber testing equipment. Together, let's unlock the full potential of your rubber materials and drive success in your industry.

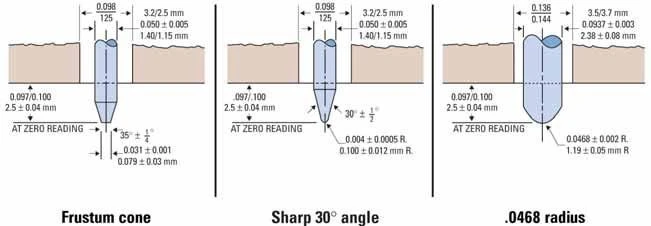

Indender Specification

Scale Selection Guide

The durometer selection guide will help you select the appropriate Shore hardness tester for your application. The combination of spring force and indenter geometry per ASTM D 2240-04 (as defined by ASTM DIN 53505, ISO 7619-1 and ASTM D 2240) determines the type of durometer required for a particular application. There is not one type of durometer that can cover the entire hardness spectrum. When selecting a durometer it is important to take the readings into consideration (readings below 10 or above 90 are not considered reliable). In such cases the next appropriate scale should be chosen.

| Scale of Durometer | Material to be used | Conforms to | Maximum Force | Indenter |

|---|---|---|---|---|

| A | Rubber : soft vulcanized (ie tire), natural nitrile. Elastomeric Materials (rubber & rubber like); GR-S,GR-1, neoprene, Thiokol, flexible polyacrylic ester. Other : wax, felt, leather, etc. (materials that normally yield under fingermail pressure such as the heel on you shoe). | ASTM D 2240 DIN 53505 |

821g | Frustum cone |

| B | Rubber: moderately hard (ie typewriter rollers, platens, etc.) | ASTM D 2240 DIN 53505 |

821 g | Sharp 30ºAngle |

| C | Rubber: medium hard Plastics : medium hard |

ASTM D 2240 DIN 53505 |

4533 g | Frustum Cone |

| D | Rubber, Hard Plastics: harder grades such as rigid thermoplastics, plexiglas, thermopolystyrene, vinyl, sheet, cellulode acetate, thermosetting laminates (ie formica) other : paper filled calendar rolls, calendar bowls, etc. (materials that would not normally indent under fingermail pressure, such as a pocket comb) | ASTM D 2240 DIN 53505 |

4533 g | Sharp 30ºAngle |

| DO | Textile Windings : very dense, slasher beams, etc. | ASTM D 2240 DIN 53505 |

4533 g | 0.0468 radius |

| E | Soft rubber, sponges and foams | ASTM D 2240 DIN 53505 |

821 g | 0.0980 radius |

| O | Rubber : soft (ie soft printer rolls, artgum) Textile Windings : medium density (ie rayon, orlon, nylon) |

ASTM D 2240 DIN 53505 |

821 g | 0.0468 radius |

| OO | Textile Windings : low density Other : sponge rubber and plastics (not for use on foamed latex) | ASTM D 2240 DIN 53505 |

113 g | 0.0468 radius |

| OOO | Plastic Foams : suit foams, open or closed cells | ASTM D 2240 DIN 53505 |

113 g | 0.25 radius |

| OOO - S | Plastic Foams : suit foams, open or closed cells | ASTM D 2240 DIN 53505 |

113 g | 0.25 radius |

| T | Textile Windings : medium density (on spools and bobbins with a maximum diameter of 101.6mm

94in)) Note : all XT’s have a concave bottom plate to facilitate centering or round specimens |

821 g | 3/32 in sphere | |

| M | Rubber : o rings and thin sheet min 1.25mm (0.05 in) thick. Complete with stand | ASTM D 2240 DIN 53505 |

78 g | Sharp 30ºAngle |